AISI Inconel 625 pipa kapiler baja tahan karat

Range produksi:

tabung kumparan stainless steel

kumparan tabung stainless steel

pipa kumparan stainless steel

pipa kumparan stainless steel

pemasok tabung coil stainless steel

produsen tabung kumparan stainless steel

kumparan pipa stainless steel

Kapiler stainless steel, tabung cilik stainless steel digunakake digunakake ing perawatan medis, serat optik, nggawe pena, produk welding elektronik, sambungan kabel cahya, pangan, Vintage, susu, ngombe, farmasi lan biokimia, dawa beda bisa kasedhiya miturut panjalukan

tabung kapiler karo bolongan maksimum 0,0158 in., kasedhiya ing sawetara saka sudhut stainless steels. Tabung kapiler Sandvik ditondoi kanthi toleransi sing nyenyet, lan permukaan njero tabung bebas saka lenga, pelumas lan partikel liyane. Iki njamin, contone, aliran cairan lan gas sing dioptimalake lan malah saka sensor menyang alat ukur.

Stainless steel Coiled tubing kasedhiya ing sawetara macem-macem formulir produk gumantung ing syarat customer. Bahan baja tahan karat Licancheng sihe ngasilake produk tabung sing dilas lan mulus. Kelas standar yaiku 304 304L 316L(UNS S31603) Duplex 2205 (UNS S32205 & S31803) Super Duplex 2507 (UNS S32750) Incoloy 825 (UNS N08825) Inconel N6066 saka baja tahan karat liyane (UNS N08825) superduplex lan alloy nikel kasedhiya ing request.

Dhiameter saka 3mm (0.118 inci) nganti 25.4mm (1.00 inci) OD. Kekandelan tembok saka 0.5mm (0.020 '') kanggo 3mm (0.118 '') .Tubing bisa diwenehake ing annealed utawa kadhemen makarya kondisi pipe line kontrol stainless steel.

Spesifikasi

| Merk | Liaocheng Sihe Stainless Steel |

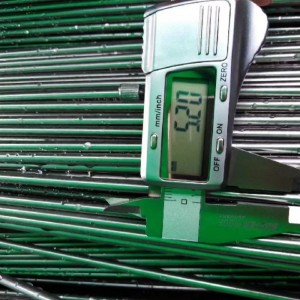

| kekandelan | 0,1-2,0 mm |

| Dhiameter | 0.3-20mm (toleransi: ± 0.01mm) |

| Kelas Stainless | 201,202,304,304L,316L,317L,321,310s,254mso,904L,2205,625 etc. |

| Lumahing Rampung | njero lan njaba padha annealing padhang, reresik, lan rapi, ora bocor. |

| Standar | ASTM A269-2002.JIS G4305/ GB/T 12770-2002GB/T12771-2002 |

| dawa | 200-1500m saben kumparan, utawa Minangka customer dibutuhake |

| Ukuran saham | 6*1mm, 8*0.5mm, 8*0.6mm, 8*0.8mm, 8*0.9mm, 8*1mm, 9.5*1mm, 10*1mm, etc. |

| Sertifikat | ISO & BV |

| Cara packing | Kantong anyaman, kantong plastik dll. |

| Range aplikasi | digunakake ing industri pangan, peralatan wedang, mesin bir, exchanger panas, susu / sistem sumber banyu, medical equipmentsolar energi, peralatan medical, aviation, aerospace, komunikasi, lenga lan industri liyane |

| Cathetan | OEM / ODM / Label Pembeli ditampa. |

| Ukuran Stainless Steel Coil Tube | ||||||||||||||||

| ITEM | sasmita | Ukuran | Tekanan | dawa | ||||||||||||

| 1 | 316L, 304L, 304 campuran 625 825 2205 2507 | 1/8″ × 0,025″ | 3200 | 500-35000 | ||||||||||||

| 2 | 316L, 304L, 304 campuran 625 825 2205 2507 | 1/8″ × 0,035″ | 3200 | 500-35000 | ||||||||||||

| 3 | 316L, 304L, 304 campuran 625 825 2205 2507 | 1/4″ × 0,035″ | 2000 | 500-35000 | ||||||||||||

| 4 | 316L, 304L, 304 campuran 625 825 2205 2507 | 1/4″ × 0,049″ | 2000 | 500-35000 | ||||||||||||

| 5 | 316L, 304L, 304 campuran 625 825 2205 2507 | 3/8″ × 0,035″ | 1500 | 500-35000 | ||||||||||||

| 6 | 316L, 304L, 304 campuran 625 825 2205 2507 | 3/8″ × 0,049″ | 1500 | 500-35000 | ||||||||||||

| 7 | 316L, 304L, 304 campuran 625 825 2205 2507 | 1/2″ × 0,049″ | 1000 | 500-35000 | ||||||||||||

| 8 | 316L, 304L, 304 campuran 625 825 2205 2507 | 1/2″ × 0,065″ | 1000 | 500-35000 | ||||||||||||

| 9 | 316L, 304L, 304 campuran 625 825 2205 2507 | φ3mm × 0.7mm | 3200 | 500-35000 | ||||||||||||

| 10 | 316L, 304L, 304 campuran 625 825 2205 2507 | φ3mm × 0.9mm | 3200 | 500-35000 | ||||||||||||

| 11 | 316L, 304L, 304 campuran 625 825 2205 2507 | φ4mm × 0.9mm | 3000 | 500-35000 | ||||||||||||

| 12 | 316L, 304L, 304 campuran 625 825 2205 2507 | φ4mm × 1.1mm | 3000 | 500-35000 | ||||||||||||

| 13 | 316L, 304L, 304 campuran 625 825 2205 2507 | φ6mm × 0.9mm | 2000 | 500-35000 | ||||||||||||

| 14 | 316L, 304L, 304 campuran 625 825 2205 2507 | φ6mm × 1.1mm | 2000 | 500-35000 | ||||||||||||

| 15 | 316L, 304L, 304 campuran 625 825 2205 2507 | φ8mm × 1mm | 1800 | 500-35000 | ||||||||||||

| 16 | 316L, 304L, 304 campuran 625 825 2205 2507 | φ8mm × 1.2mm | 1800 | 500-35000 | ||||||||||||

| 17 | 316L, 304L, 304 campuran 625 825 2205 2507 | φ10mm × 1mm | 1500 | 500-35000 | ||||||||||||

| 18 | 316L, 304L, 304 campuran 625 825 2205 2507 | φ10mm × 1.2mm | 1500 | 500-35000 | ||||||||||||

| 19 | 316L, 304L, 304 campuran 625 825 2205 2507 | φ10mm × 2mm | 500 | 500-35000 | ||||||||||||

| 20 | 316L, 304L, 304 campuran 625 825 2205 2507 | φ12mm × 1.5mm | 500 | 500-35000 | ||||||||||||

| Tabel tekanan | ||||||||||||||||

| Pamilihan bahan sing cocog kanggo kontrol utawa garis injeksi kimia tundhuk karo kahanan operasional lan situs sing ana. Kanggo mbantu milih, tabel ing ngisor iki nyedhiyakake rating tekanan internal lan faktor pangaturan kanggo macem-macem ukuran umum lan ukuran pipa stainless sing dilas lan laser. | ||||||||||||||||

| Tekanan maksimum (P) kanggo TP 316L ing 100°F (38°C)1) | ||||||||||||||||

| Mangga deleng faktor pangaturan tingkat lan wangun produk ing ngisor iki. | ||||||||||||||||

| Diameter njaba, ing. | Ketebalan tembok, ing. | Tekanan kerja2) | Tekanan burst2) | Tekanan ambruk4) | ||||||||||||

| psi (MPa) | psi (MPa) | psi (MPa) | ||||||||||||||

| 1/4 | 0.035 | 6.600 (46) | 22.470 (155) | 6.600 (46) | ||||||||||||

| 1/4 | 0.049 | 9.260 (64) | 27.400 (189) | 8.710 (60) | ||||||||||||

| 1/4 | 0,065 | 12.280 (85) | 34.640 (239) | 10.750 (74) | ||||||||||||

| 3/8 | 0.035 | 4.410 (30) | 19.160 (132) | 4.610 (32) | ||||||||||||

| 3/8 | 0.049 | 6.170 (43) | 21.750 (150) | 6.220 (43) | ||||||||||||

| 3/8 | 0,065 | 8.190 (56) | 25.260 (174) | 7.900 (54) | ||||||||||||

| 3/8 | 0.083 | 10.450 (72) | 30.050 (207) | 9.570 (66) | ||||||||||||

| 1/2 | 0.049 | 4.630 (32) | 19.460 (134) | 4.820 (33) | ||||||||||||

| 1/2 | 0,065 | 6.140 (42) | 21.700 (150) | 6.200 (43) | ||||||||||||

| 1/2 | 0.083 | 7.840 (54) | 24.600 (170) | 7.620 (53) | ||||||||||||

| 5/8 | 0.049 | 3.700 (26) | 18.230 (126) | 3.930 (27) | ||||||||||||

| 5/8 | 0,065 | 4.900 (34) | 19.860 (137) | 5.090 (35) | ||||||||||||

| 5/8 | 0.083 | 6.270 (43) | 26.910 (151) | 6.310 (44) | ||||||||||||

| 3/4 | 0.049 | 3.080 (21) | 17.470 (120) | 3.320 (23) | ||||||||||||

| 3/4 | 0,065 | 4.090 (28) | 18.740 (129) | 4.310 (30) | ||||||||||||

| 3/4 | 0.083 | 5.220 (36) | 20.310 (140) | 5.380 (37) | ||||||||||||

| 1) Mung taksiran. Tekanan nyata kudu diitung kanthi nimbang kabeh faktor stres ing sistem. | ||||||||||||||||

| 2) Adhedhasar petungan saka API 5C3, nggunakake toleransi tembok +/-10% | ||||||||||||||||

| 3) Adhedhasar petungan bledosan kekuatan pokok saka API 5C3 | ||||||||||||||||

| 4) Adhedhasar petungan ambruk kekuatan ngasilaken saka API 5C3 | ||||||||||||||||

| Faktor pangaturan kanggo watesan tekanan kerja1) | ||||||||||||||||

| Pw = peringkat tekanan kerja referensi kanggo TP 316L ing 100°F (38°C). Kanggo nemtokake tekanan kerja kanggo kombinasi kelas/suhu, multiply Pw dening faktor pangaturan. | ||||||||||||||||

| sasmita | 100°F | 200°F | 300°F | 400°F | ||||||||||||

| (38°C) | (93°C) | (149°C) | (204°C) | |||||||||||||

| TP 316L, mulus | 1 | 0.87 | 0.7 | 0.63 | ||||||||||||

| TP 316L, gandheng | 0.85 | 0.74 | 0.6 | 0.54 | ||||||||||||

| Alloy 825, mulus | 1.33 | 1.17 | 1.1 | 1.03 | ||||||||||||

| Alloy 825, gandheng | 1.13 | 1.99 | 1.94 | 0.88 | ||||||||||||

| 1) faktor pangaturan adhedhasar kaku allowable ing ASME. | ||||||||||||||||

| Faktor pangaturan kanggo watesan tekanan burst1) | ||||||||||||||||

| Pb = tekanan burst referensi kanggo TP 316L ing 100°F. Kanggo nemtokake tekanan bledosan kanggo kombinasi kelas/suhu, multiply Pb dening faktor pangaturan. | ||||||||||||||||

| sasmita | 100°F | 200°F | 300°F | 400°F | ||||||||||||

| (38°C) | (93°C) | (149°C) | (204°C) | |||||||||||||

| TP 316L, mulus | 1 | 0.93 | 0.87 | 0.8 | ||||||||||||

| TP 316L, gandheng | 0.85 | 0.79 | 0.74 | 0.68 | ||||||||||||

| Alloy 825, mulus | 1.13 | 1.07 | 1 | 0.87 | ||||||||||||

| Alloy 825, gandheng | 0.96 | 0.91 | 0.85 | 0.74 | ||||||||||||

| 1) Faktor pangaturan adhedhasar kekuatan pokok ing ASME. | ||||||||||||||||

▼Stainless steel coiled tubing/coiled tubes bahan kelas:

| USA | JERMAN | JERMAN | FRANCE | JEPUN | ITALIA | SWEDEN | UK | EU | SPANYOL | RUSIA |

| AISI | DIN 17006 | WN 17007 | AFNOR | JIS | UNI | SIS | BSI | EURONORM | ||

| 201 | SUS 201 | |||||||||

| 301 | X 12 KrNi 17 7 | 1.4310 | Z 12 CN 17-07 | SUS 301 | X 12 CrNi 1707 | 23 31 | 301S21 | X 12 KrNi 17 7 | X 12 CrNi 17-07 | |

| 302 | X 5 KrNi 18 7 | 1.4319 | Z 10 CN 18-09 | SUS 302 | X 10 CrNi 1809 | 23 31 | 302S25 | X 10 KrNi 18 9 | X 10 CrNi 18-09 | 12KH18N9 |

| 303 | X 10 CrNiS 18 9 | 1.4305 | Z 10 CNF 18-09 | SUS 303 | X 10 CrNiS 1809 | 23 46 | 303S21 | X 10 CrNiS 18 9 | X 10 CrNiS 18-09 | |

| 303 Se | Z 10 CNF 18-09 | SUS 303 Se | X 10 CrNiS 1809 | 303S41 | X 10 CrNiS 18-09 | 12KH18N10E | ||||

| 304 | X 5 KrNi 18 10 X 5 KrNi 18 12 | 1.4301 1.4303 | Z 6 CN 18-09 | SUS 304 | X 5 CrNi 1810 | 23 32 | 304S15 304S16 | X 6 KrNi 18 10 | X 6 KrNi 19-10 | 08KH18N10 06KH18N11 |

| 304 N | SUS 304N1 | X 5 CrNiN 1810 | ||||||||

| 304 H | SUS F 304H | X 8 KrNi 1910 | X 6 KrNi 19-10 | |||||||

| 304 L | X 2 KrNi 18 11 | 1.4306 | Z 2 CN 18-10 | SUS 304L | X 2 KrNi 1911 | 23 52 | 304S11 | X 3 KrNi 18 10 | X 2 KrNi 19-10 | 03KH18N11 |

| X 2 CrNiN 18 10 | 1.4311 | Z 2 CN 18-10-Az | SUS 304LN | X 2 CrNiN 1811 | 23 71 | |||||

| 305 | Z 8 CN 18-12 | SUS 305 | X 8 KrNi 1812 | 23 33 | 305S19 | X 8 KrNi 18 12 | X 8 KrNi 18-12 | |||

| Z 6 CNU 18-10 | SUS XM7 | X 6 CrNiCu 18 10 4 Kd | ||||||||

| 309 | X 15 CrNiS 20 12 | 1.4828 | Z 15 CN 24-13 | SUH 309 | X 16 CrNi 2314 | 309S24 | X 15 KrNi 23 13 | |||

| 309 S | SUS 309S | X 6 CrNi 2314 | X 6 KrNi 22 13 | |||||||

| 310 | X 12 KrNi 25 21 | 1.4845 | SUH 310 | X 22 CrNi 2520 | 310S24 | 20KH23N18 | ||||

| 310 S | X 12 KrNi 25 20 | 1.4842 | Z 12 CN 25-20 | SUS 310S | X 5 CrNi 2520 | 23 61 | X 6 KrNi 25 20 | 10KH23N18 | ||

| 314 | X 15 CrNiSi 25 20 | 1.4841 | Z 12 CNS 25-20 | X 16 CrNiSi 2520 | X 15 CrNiSi 25 20 | 20KH25N20S2 | ||||

| 316 | X 5 CrNiMo 17 12 2 | 1.4401 | Z 6 CND 17-11 | SUS 316 | X 5 CrNiMo 1712 | 23 47 | 316S31 | X 6 CrNiMo 17 12 2 | X 6 CrNiMo 17-12-03 | |

| 316 | X 5 CrNiMo 17 13 3 | 1.4436 | Z 6 CND 17-12 | SUS 316 | X 5 CrNiMo 1713 | 23 43 | 316S33 | X 6 CrNiMo 17 13 3 | X 6 CrNiMo 17-12-03 | |

| 316 F | X 12 CrNiMoS 18 11 | 1.4427 | ||||||||

| 316 N | SUS 316N | |||||||||

| 316 H | SUS F 316H | X 8 CrNiMo 1712 | X 5 CrNiMo 17-12 | |||||||

| 316 H | X 8 CrNiMo 1713 | X 6 CrNiMo 17-12-03 | ||||||||

| 316 L | X 2 CrNiMo 17 13 2 | 1.4404 | Z 2 CND 17-12 | SUS 316L | X 2 CrNiMo 1712 | 23 48 | 316S11 | X 3 CrNiMo 17 12 2 | X 2 CrNiMo 17-12-03 | 03KH17N14M2 |

| X 2 KrNiMoN 17 12 2 | 1.4406 | Z 2 CND 17-12-Az | SUS 316LN | X 2 CrNiMoN 1712 | ||||||

| 316 L | X 2 CrNiMo 18 14 3 | 1.4435 | Z 2 CND 17-13 | X 2 CrNiMo 1713 | 23 53 | 316S13 | X 3 CrNiMo 17 13 3 | X 2 CrNiMo 17-12-03 | 03KH16N15M3 | |

| X 2 KrNiMoN 17 13 3 | 1.4429 | Z 2 CND 17-13-Az | X 2 CrNiMoN 1713 | 23 75 | ||||||

| X 6 CrNiMoTi 17 12 2 | 1.4571 | Z6 CNDT 17-12 | X 6 CrNiMoTi 1712 | 23 50 | 320S31 | X 6 CrNiMoTi 17 12 2 | X 6 CrNiMoTi 17-12-03 | 08KH17N13M2T 10KH17N13M2T | ||

| X 10 CrNiMoTi 18 12 | 1.4573 | X 6 CrNiMoTi 1713 | 320S33 | X 6 CrNiMoTI 17 13 3 | X 6 CrNiMoTi 17-12-03 | 08KH17N13M2T 10KH17N13M2T | ||||

| X 6 CrNiMoNb 17 12 2 | 1.4580 | Z 6 CDNb 17-12 | X 6 CrNiMoNb 1712 | X 6 CrNiMoNb 17 12 2 | 08KH16N13M2B | |||||

| X 10 CrNiMoNb 18 12 | 1.4583 | X 6 CrNiMoNb 1713 | X 6 CrNiMoNb 17 13 3 | 09KH16N15M3B | ||||||

| 317 | SUS 317 | X 5 CrNiMo 1815 | 23 66 | 317S16 | ||||||

| 317 L | X 2 CrNiMo 18 16 4 | 1.4438 | Z 2 CND 19-15 | SUS 317L | X 2 CrNiMo 1815 | 23 67 | 317S12 | X 3 CrNiMo 18 16 4 | ||

| 317 L | X 2 CrNiMo 18 16 4 | 1.4438 | Z 2 CND 19-15 | SUS 317L | X 2 CrNiMo 1816 | 23 67 | 317S12 | X 3 CrNiMo 18 16 4 | ||

| 330 | X 12 NiCrSi 36 16 | 1.4864 | Z 12NCS 35-16 | SUH 330 | ||||||

| 321 | X 6 KrNiTi 18 10 X 12 KrNiTi 18 9 | 1.4541 1.4878 | Z 6 CNT 18-10 | SUS 321 | X 6 CrNiTi 1811 | 23 37 | 321S31 | X 6 KrNiTi 18 10 | X 6 CrNiTi 18-11 | 08KH18N10T |

| 321 H | SUS 321H | X 8 CrNiTi 1811 | 321S20 | X 7 KrNiTi 18-11 | 12KH18N10T | |||||

| 329 | X 8 CrNiMo 27 5 | 1.4460 | SUS 329J1 | 23 24 | ||||||

| 347 | X 6 CrNiNb 18 10 | 1.4550 | Z 6 CNNb 18-10 | SUS 347 | X 6 CrNiNb 1811 | 23 38 | 347S31 | X 6 CrNiNb 18 10 | X 6 CrNiNb 18-11 | 08KH18N12B |

| 347 H | SUS F 347H | X 8 CrNiNb 1811 | X 7 CrNiNb 18-11 | |||||||

| 904L | 1.4939 | Z 12 CNCV 12-02 | ||||||||

| X 20 CrNiSi 25 4 | 1.4821 | |||||||||

| UNS31803 | X 2 KrNiMoN 22 5 | 1.4462 | ||||||||

| UNS32760 | X 3 KrNiMoN 25 7 | 1.4501 | Z 3 CND 25-06Az | |||||||

| 403 | X 6 Kr 13 X 10 Kr 13 X 15 Kr 13 | 1.4000 1.4006 1.4024 | Z 12 C 13 | SUS 403 | X 12 Kr 13 | 23 02 | 403S17 | X 10 Kr 13 X 12 Kr 13 | X 6 Kr 13 | 12Kh13 |

| 405 | X 6 KrAl 13 | 1.4002 | Z 6 CA 13 | SUS 405 | X 6 KrAl 13 | 405S17 | X 6 KrAl 13 | X 6 KrAl 13 | ||

| X 10 KrAl 7 | 1.4713 | Z 8 CA 7 | X 10 KrAl 7 | |||||||

| X 10 KrAl 13 | 1.4724 | X 10 KrAl 12 | 10Kh13SYu | |||||||

| X 10 KrAl 18 | 1.4742 | X 10 CrSiAl 18 | 15Kh18SYu | |||||||

| 409 | X 6 KrTi 12 | 1.4512 | Z 6 CT 12 | SUH 409 | X 6 KrTi 12 | 409S19 | X 5 KrTi 12 | |||

| X 2 KrTi 12 | ||||||||||

| 410 | X 6 Kr 13 X 10 Kr 13 X 15 Kr 13 | 1.4000 1.4006 1.4024 | Z 10 C 13 Z 12 C 13 | SUS 410 | X 12 Kr 13 | 23 02 | 410S21 | X 12 Kr 13 | X 12 Kr 13 | 12Kh13 |

| 410 S | X 6 Kr 13 | 1.4000 | Z 6 C 13 | SUS 410S | X 6 Kr 13 | 23 01 | 403S17 | X 6 Kr 13 | 08Kh13 | |

| 414 |

Pabrik

Keuntungan kualitas:

Kualitas produk kita kanggo garis kontrol ing sektor minyak lan gas dijamin ora mung sajrone proses manufaktur sing dikontrol nanging uga kanthi tes produk rampung. Tes khas kalebu:

1. Tes sing ora ngrusak

2. Tes hidrostatik

3. Kontrol Rampung lumahing

4. Pangukuran akurasi dimensi

5. Tes flare lan coning

6. Pengujian sifat mekanik lan kimia

Aplikasi tabung cailer

1) Industri piranti medis

2) kontrol suhu industri sing dipandu suhu, sensor digunakake pipa, termometer tabung

3) Pens care industri tabung inti

4) antena mikro-tabung, macem-macem jinis antena stainless steel presisi cilik

5) Kanthi macem-macem kapiler stainless steel diameter cilik elektronik

6) Punch jarum perhiasan

7) Jam tangan, gambar

8) Tabung antena mobil, antena bar nggunakake tabung, tabung antena

9) peralatan laser engraving kanggo nggunakake tabung stainless steel

10) peralatan Fishing, aksesoris, Yugan metu karo milik saka

11) Diet karo kapiler stainless steel

12) kabeh jinis stylus ponsel lan stylus komputer

13) Industri pipa pemanas, industri minyak

14) Printer, jarum kothak bisu

15) Narik tabung stainless steel pindho nyawiji digunakake ing jendhela-gandeng

16) A macem-macem industri cilik diameteripun Precision tabung stainless steel

17) Precision dispensing karo jarum stainless steel

18) Mikropon, headphone lan mikropon kanggo nggunakake tabung stainless steel, lan liya-liyane