Tubus capillaris chalybis inoxidabilis Inconel 625 (UNS N06625)

Series fabricationis:

tubus spiralis chalybis inoxidabilis

spira tubuli chalybis inoxidabilis

tubi spirales chalybis inoxidabilis

tubus spiralis chalybis inoxidabilis

Tubi spirales chalybis inoxidabilis praebitores

Fabricatores tuborum spiralium chalybis inoxidabilis

spira tubi chalybis inoxidabilis

Capillare chalybeum inoxidabile, tubus parvus chalybeus inoxidabilis late adhibetur in curatione medica, fibra optica, calamo confecto, productis electronicis ad ferruminandum, iunctura funium lucis, cibo, arte antiqua, lacticiniis, potibus, pharmacopoliis et biochemia; variae longitudines secundum petitiones praeberi possunt.

Tubi capillares cum diametro maximo 0.0158 in., in ampla varietate chalybum inoxidabilium praesto. Tubi capillares Sandvik tolerantiis strictis insigniuntur, et superficies interna tuborum libera est ab oleo, adipe, aliisque particulis. Hoc, exempli gratia, fluxum liquidorum et gasorum a sensore ad instrumentum mensurae optimizatum et aequabilem praestat.

Tubi spirales ex chalybe inoxidabili variis formis praesto sunt, secundum necessitates emptoris. Licancheng sihe, materia chalybis inoxidabilis, tubos et conglutinatos et sine suturis fabricat. Genera ordinaria sunt: 304, 304L, 316L (UNS S31603), Duplex 2205 (UNS S32205 et S31803), Super Duplex 2507 (UNS S32750), Incoloy 825 (UNS N08825), Inconel 625 (UNS N06625). Alia genera chalybis inoxidabilis, duplex et superduplex, necnon mixturae niccoli, si petantur, praesto sunt.

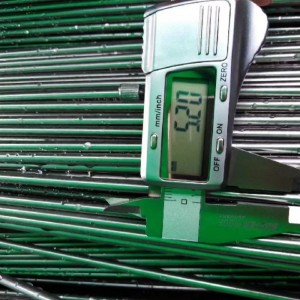

Diametros a 3mm (0.118'') ad 25.4mm (1.00'') ext. Crassitudo parietis a 0.5mm (0.020'') ad 3mm (0.118''). Tubi in statu tubi gubernatorii ex chalybe inoxidabili, sive recocti sive frigidi, suppeditari possunt.

Specificatio

| Nota | Liaocheng Sihe STEEL |

| Crassitudo | 0.1-2.0mm |

| Diameter | 0.3-20mm (tolerantia: ±0.01mm) |

| Gradus Inoxidabilis | 201, 202, 304, 304L, 316L, 317L, 321, 310s, 254mso, 904L, 2205, 625 etc. |

| Superficies Finis | Intus et extra sunt et nitida recoctione, purgatione, et sine ulla stillatione. |

| Norma | ASTM A269-2002.JIS G4305/ GB/T 12770-2002GB/T 12771-2002 |

| Longitudo | 200-1500m per spiram, vel prout emptor requirit |

| Magnitudo copiae | 6*1mm, 8*0.5mm, 8*0.6mm, 8*0.8mm, 8*0.9mm, 8*1mm, 9.5*1mm, 10*1mm, et cetera. |

| Certificatum | ISO&BV |

| Modus sarcinandi | Sacci texti, sacci plastici, etc. |

| Ambitus applicationis | late adhibitum in industria cibaria, apparatu potionum, machina cerevisiae, permutatore caloris, systemate lactis/aquae, apparatu medico, energia solari, apparatu medico, aviatione, aerospatio, communicationibus, oleo et aliis industriis. |

| Nota | Titulus OEM / ODM / Emptoris acceptus. |

| Magnitudo Tubi Spiralis Chalybis Inoxidabilis | ||||||||||||||||

| RES | Gradus | Magnitudo | Pressio | Longitudo | ||||||||||||

| 1 | 316L, 304L, 304 mixturae metallicae, 625, 825, 2205, 2507 | 1/8″ × 0.025″ | 3200 | 500-35000 | ||||||||||||

| 2 | 316L, 304L, 304 mixturae metallicae, 625, 825, 2205, 2507 | 1/8″ × 0.035″ | 3200 | 500-35000 | ||||||||||||

| 3 | 316L, 304L, 304 mixturae metallicae, 625, 825, 2205, 2507 | 1/4″ × 0.035″ | MM | 500-35000 | ||||||||||||

| 4 | 316L, 304L, 304 mixturae metallicae, 625, 825, 2205, 2507 | 1/4″ × 0.049″ | MM | 500-35000 | ||||||||||||

| 5 | 316L, 304L, 304 mixturae metallicae, 625, 825, 2205, 2507 | 3/8″ × 0.035″ | 1500 | 500-35000 | ||||||||||||

| 6 | 316L, 304L, 304 mixturae metallicae, 625, 825, 2205, 2507 | 3/8″ × 0.049″ | 1500 | 500-35000 | ||||||||||||

| 7 | 316L, 304L, 304 mixturae metallicae, 625, 825, 2205, 2507 | 1/2″ × 0.049″ | mille | 500-35000 | ||||||||||||

| 8 | 316L, 304L, 304 mixturae metallicae, 625, 825, 2205, 2507 | 1/2″ × 0.065″ | mille | 500-35000 | ||||||||||||

| 9 | 316L, 304L, 304 mixturae metallicae, 625, 825, 2205, 2507 | φ3mm × 0.7mm | 3200 | 500-35000 | ||||||||||||

| 10 | 316L, 304L, 304 mixturae metallicae, 625, 825, 2205, 2507 | φ3mm × 0.9mm | 3200 | 500-35000 | ||||||||||||

| 11 | 316L, 304L, 304 mixturae metallicae, 625, 825, 2205, 2507 | φ4mm × 0.9mm | tria milia | 500-35000 | ||||||||||||

| 12 | 316L, 304L, 304 mixturae metallicae, 625, 825, 2205, 2507 | φ4mm × 1.1mm | tria milia | 500-35000 | ||||||||||||

| 13 | 316L, 304L, 304 mixturae metallicae, 625, 825, 2205, 2507 | φ6mm × 0.9mm | MM | 500-35000 | ||||||||||||

| 14 | 316L, 304L, 304 mixturae metallicae, 625, 825, 2205, 2507 | φ6mm × 1.1mm | MM | 500-35000 | ||||||||||||

| 15 | 316L, 304L, 304 mixturae metallicae, 625, 825, 2205, 2507 | φ8mm × 1mm | MDCCC | 500-35000 | ||||||||||||

| 16 | 316L, 304L, 304 mixturae metallicae, 625, 825, 2205, 2507 | φ8mm × 1.2mm | MDCCC | 500-35000 | ||||||||||||

| 17 | 316L, 304L, 304 mixturae metallicae, 625, 825, 2205, 2507 | φ10mm × 1mm | 1500 | 500-35000 | ||||||||||||

| 18 | 316L, 304L, 304 mixturae metallicae, 625, 825, 2205, 2507 | φ10mm × 1.2mm | 1500 | 500-35000 | ||||||||||||

| 19 | 316L, 304L, 304 mixturae metallicae, 625, 825, 2205, 2507 | φ10mm × 2mm | quingenti | 500-35000 | ||||||||||||

| 20 | 316L, 304L, 304 mixturae metallicae, 625, 825, 2205, 2507 | φ12mm × 1.5mm | quingenti | 500-35000 | ||||||||||||

| Tabulae pressionis | ||||||||||||||||

| Delectus materiae idoneae pro quavis linea moderationis vel injectionis chemicae condicionibus operationis et situs praevalentibus pendet. Ut in delectu auxilium ferant, tabulae sequentes aestimationes pressionis internae et factores adaptationis pro variis generibus et magnitudinibus communibus tuborum inoxidabilium sine suturis et lasere conglutinatorum praebent. | ||||||||||||||||

| Pressio maxima (P) pro TP 316L ad 100°F (38°C)1) | ||||||||||||||||

| Quaeso, factores adaptationis gradus et formae producti infra vide. | ||||||||||||||||

| Diameter externus, in | Crassitudo parietis, ind. | Pressio operandi2) | Pressio rupturae2) | Pressio collapsus4) | ||||||||||||

| psi (MPa) | psi (MPa) | psi (MPa) | ||||||||||||||

| Quarta pars | 0.035 | 6600 (46) | 22,470 (155) | 6600 (46) | ||||||||||||

| Quarta pars | 0.049 | 9,260 (64) | 27,400 (189) | 8,710 (60) | ||||||||||||

| Quarta pars | 0.065 | XII,CCLXXX (LXXXV) | 34,640 (239) | 10,750 (74) | ||||||||||||

| 3/8 | 0.035 | 4410 (30) | 19,160 (132) | 4,610 (32) | ||||||||||||

| 3/8 | 0.049 | 6,170 (43) | XXI,DCCL (CL) | 6,220 (43) | ||||||||||||

| 3/8 | 0.065 | 8,190 (56) | XXV,CCLX (CLXXIV) | 7,900 (54) | ||||||||||||

| 3/8 | 0.083 | 10,450 (72) | 30,050 (207) | 9,570 (66) | ||||||||||||

| Dimidium | 0.049 | 4630 (32) | 19,460 (134) | 4820 (33) | ||||||||||||

| Dimidium | 0.065 | 6,140 (42) | XXI,DCC (CL) | 6200 (43) | ||||||||||||

| Dimidium | 0.083 | 7,840 (54) | 24,600 (170) | 7,620 (53) | ||||||||||||

| 5/8 | 0.049 | 3700 (26) | XVIII,CCXXX (CXXVI) | 3930 (27) | ||||||||||||

| 5/8 | 0.065 | 4900 (34) | 19,860 (137) | 5,090 (35) | ||||||||||||

| 5/8 | 0.083 | 6,270 (43) | XXVI,DCX (CLI) | 6,310 (44) | ||||||||||||

| Tres quartae partes | 0.049 | 3080 (21) | 17,470 (120) | 3320 (23) | ||||||||||||

| Tres quartae partes | 0.065 | 4090 (28) | XVIII,DCCXL (CXXIX) | 4310 (30) | ||||||||||||

| Tres quartae partes | 0.083 | 5220 (36) | 20,310 (140) | 5,380 (37) | ||||||||||||

| 1) Aestimationes tantum. Pressiones reales computandae sunt omnibus factoribus tensionis in systemate consideratis. | ||||||||||||||||

| 2) Secundum calculationes ex API 5C3, tolerantia parietis +/-10% adhibita. | ||||||||||||||||

| 3) Secundum calculationes rupturae roboris ultimi ex API 5C3 | ||||||||||||||||

| 4) Secundum calculationes collapsus roboris cessionis ex API 5C3 | ||||||||||||||||

| Factores adaptationis pro limitibus pressionis operativae1) | ||||||||||||||||

| Pw = aestimatio pressionis operativae referentialis pro TP 316L ad 100°F (38°C). Ad pressionem operativam pro combinatione gradus/temperaturae determinandam, Pw multiplica per factorem adaptationis. | ||||||||||||||||

| Gradus | centum°F | ducenti°F | trecenti°F | quadringenti°F | ||||||||||||

| (XXXVIII)°C) | (93)°C) | (149)°C) | (204)°C) | |||||||||||||

| TP 316L, sine sutura | 1 | 0.87 | 0.7 | 0.63 | ||||||||||||

| TP 316L, conglutinatum | 0.85 | 0.74 | 0.6 | 0.54 | ||||||||||||

| Mixtura 825, sine suturis | 1.33 | 1.17 | 1.1 | 1.03 | ||||||||||||

| Mixtura 825, conglutinata | 1.13 | 1.99 | 1.94 | 0.88 | ||||||||||||

| 1) Factores adaptationis secundum tensionem permissam in ASME fundati. | ||||||||||||||||

| Factores adaptationis pro limitibus pressionis rupturae1) | ||||||||||||||||

| Pb = pressio rupturae referentialis pro TP 316L ad 100°F. Ad pressionem rupturae pro combinatione gradus/temperaturae determinandam, Pb multiplica per factorem adaptationis. | ||||||||||||||||

| Gradus | centum°F | ducenti°F | trecenti°F | quadringenti°F | ||||||||||||

| (XXXVIII)°C) | (93)°C) | (149)°C) | (204)°C) | |||||||||||||

| TP 316L, sine sutura | 1 | 0.93 | 0.87 | 0.8 | ||||||||||||

| TP 316L, conglutinatum | 0.85 | 0.79 | 0.74 | 0.68 | ||||||||||||

| Mixtura 825, sine suturis | 1.13 | 1.07 | 1 | 0.87 | ||||||||||||

| Mixtura 825, conglutinata | 0.96 | 0.91 | 0.85 | 0.74 | ||||||||||||

| 1) Factores adaptationis secundum firmitatem ultimam in ASME fundati. | ||||||||||||||||

▼Tubi spirales chalybis inoxidabilis / gradus materiae tuborum spiralium:

| Civitates Foederatae Americae | GERMANIA | GERMANIA | GALLIA | IAPONIA | ITALIA | Suecia | Britanniarum Regnum | Unio Europaea | HISPANIA | RUSSIA |

| AISI | DIN 17006 | WN 17007 | AFNOR | JIS | UNI | SIS | BSI | EURONORM | ||

| 201 | SUS 201 | |||||||||

| 301 | X 12 CrNi 17 7 | 1.4310 | Z 12 CN 17-07 | SUS 301 | X 12 CrNi 1707 | XXIII XXXI | 301S21 | X 12 CrNi 17 7 | X 12 CrNi 17-07 | |

| 302 | X 5 CrNi 18 7 | 1.4319 | Z 10 CN 18-09 | SUS 302 | X 10 CrNi 1809 | XXIII XXXI | 302S25 | X 10 CrNi 18 9 | X 10 CrNi 18-09 | 12KH18N9 |

| 303 | X 10 CrNiS 18 9 | 1.4305 | Z 10 CNF 18-09 | SUS 303 | X 10 CrNiS 1809 | XXIII XLVI | 303S21 | X 10 CrNiS 18 9 | X 10 CrNiS 18-09 | |

| 303 Se | Z 10 CNF 18-09 | SUS 303 Se | X 10 CrNiS 1809 | 303S41 | X 10 CrNiS 18-09 | 12KH18N10E | ||||

| 304 | X 5 CrNi 18 10 X 5 CrNi 18 12 | 1.4301 1.4303 | Z 6 CN 18-09 | SUS 304 | X 5 CrNi 1810 | XXIII XXXII | 304S15 304S16 | X 6 CrNi 18 10 | X 6 CrNi 19-10 | 08KH18N10 06KH18N11 |

| 304 N | SUS 304N1 | X 5 CrNiN 1810 | ||||||||

| 304 H | SUS F 304H | X 8 CrNi 1910 | X 6 CrNi 19-10 | |||||||

| 304 L | X²CrNi1811 | 1.4306 | Z 2 CN 18-10 | SUS 304L | X 2 CrNi 1911 | XXIII LII | 304S11 | X 3 CrNi 18 10 | X 2 CrNi 19-10 | 03KH18N11 |

| X²CrNiN1810 | 1.4311 | Z 2 CN 18-10-Az | SUS 304LN | X² CrNiN 1811 | XXIII LXXI | |||||

| CCCV | Z 8 CN 18-12 | SUS 305 | X 8 CrNi 1812 | XXIII XXXIII | 305S19 | X 8 CrNi 18 12 | X 8 CrNi 18-12 | |||

| Z 6 CNU 18-10 | SUS XM7 | X6CrNiCu18104Kd | ||||||||

| 309 | X 15 CrNiS 20 12 | 1.4828 | Z 15 CN 24-13 | SUH 309 | X 16 CrNi 2314 | 309S24 | X 15 CrNi 23 13 | |||

| 309 S | SUS 309S | X 6 CrNi 2314 | X 6 CrNi 22 13 | |||||||

| CCCX | X 12 CrNi 25 21 | 1.4845 | SUH 310 | X 22 CrNi 2520 | 310S24 | 20KH23N18 | ||||

| 310 S | X 12 CrNi 25 20 | 1.4842 | Z 12 CN 25-20 | SUS 310S | X 5 CrNi 2520 | XXIII LXI | X 6 CrNi 25 20 | 10KH23N18 | ||

| 314 | X 15 CrNiSi 25 20 | 1.4841 | Z 12 CNS 25-20 | X 16 CrNiSi 2520 | X 15 CrNiSi 25 20 | 20KH25N20S2 | ||||

| CCCXVI | X 5 CrNiMo 17 12 2 | 1.4401 | Z 6 CND 17-11 | SUS 316 | X 5 CrNiMo 1712 | XXIII XLVII | 316S31 | X 6 CrNiMo 17 12 2 | X 6 CrNiMo 17-12-03 | |

| CCCXVI | X 5 CrNiMo 17 13 3 | 1.4436 | Z 6 CND 17-12 | SUS 316 | X 5 CrNiMo 1713 | XXIII XLIII | 316S33 | X 6 CrNiMo 17 13 3 | X 6 CrNiMo 17-12-03 | |

| 316 F | X 12 CrNiMoS 18 11 | 1.4427 | ||||||||

| 316 N | SUS 316N | |||||||||

| 316 H | SUS F 316H | X 8 CrNiMo 1712 | X 5 CrNiMo 17-12 | |||||||

| 316 H | X 8 CrNiMo 1713 | X 6 CrNiMo 17-12-03 | ||||||||

| 316 L | X²CrNiMo17132 | 1.4404 | Z 2 CND 17-12 | SUS 316L | X 2 CrNiMo 1712 | XXIII XLVIII | 316S11 | X 3 CrNiMo 17 12 2 | X 2 CrNiMo 17-12-03 | 03KH17N14M2 |

| X²CrNiMoN17122 | 1.4406 | Z 2 CND 17-12-Az | SUS 316LN | X 2 CrNiMoN 1712 | ||||||

| 316 L | X 2 CrNiMo 18 14 3 | 1.4435 | Z 2 CND 17-13 | X 2 CrNiMo 1713 | XXIII LIII | 316S13 | X 3 CrNiMo 17 13 3 | X 2 CrNiMo 17-12-03 | 03KH16N15M3 | |

| X 2 CrNiMoN 17 13 3 | 1.4429 | Z 2 CND 17-13-Az | X 2 CrNiMoN 1713 | XXIII LXXV | ||||||

| X 6 CrNiMoTi 17 12 2 | 1.4571 | Z6 CNDT 17-12 | X 6 CrNiMoTi 1712 | XXIII L | 320S31 | X 6 CrNiMoTi 17 12 2 | X 6 CrNiMoTi 17-12-03 | 08KH17N13M2T 10KH17N13M2T | ||

| X 10 CrNiMoTi 18 12 | 1.4573 | X 6 CrNiMoTi 1713 | 320S33 | X 6 CrNiMoTI 17 13 3 | X 6 CrNiMoTi 17-12-03 | 08KH17N13M2T 10KH17N13M2T | ||||

| X 6 CrNiMoNb 17 12 2 | 1.4580 | Z 6 CNDNb 17-12 | X6 CrNiMoNb 1712 | X 6 CrNiMoNb 17 12 2 | 08KH16N13M2B | |||||

| X 10 CrNiMoNb 18 12 | 1.4583 | X6 CrNiMoNb 1713 | X 6 CrNiMoNb 17 13 3 | 09KH16N15M3B | ||||||

| 317 | SUS 317 | X 5 CrNiMo 1815 | XXIII LXVI | 317S16 | ||||||

| 317 L | X 2 CrNiMo 18 16 4 | 1.4438 | Z 2 CND 19-15 | SUS 317L | X 2 CrNiMo 1815 | XXIII LXVII | 317S12 | X 3 CrNiMo 18 16 4 | ||

| 317 L | X 2 CrNiMo 18 16 4 | 1.4438 | Z 2 CND 19-15 | SUS 317L | X 2 CrNiMo 1816 | XXIII LXVII | 317S12 | X 3 CrNiMo 18 16 4 | ||

| 330 | X 12 NiCrSi 36 16 | 1.4864 | Z 12NCS 35-16 | SUH 330 | ||||||

| 321 | X 6 CrNiTi 18 10 X 12 CrNiTi 18 9 | 1.4541 1.4878 | Z 6 CNT 18-10 | SUS 321 | X 6 CrNiTi 1811 | XXIII XXXVII | 321S31 | X 6 CrNiTi 18 10 | X 6 CrNiTi 18-11 | 08KH18N10T |

| 321 H | SUS 321H | X 8 CrNiTi 1811 | 321S20 | X 7 CrNiTi 18-11 | 12KH18N10T | |||||

| 329 | X 8 CrNiMo 27 5 | 1.4460 | SUS 329J1 | XXIII XXIV | ||||||

| 347 | X 6 CrNiNb 18 10 | 1.4550 | Z 6 CNNb 18-10 | SUS 347 | X6 CrNiNb 1811 | XXIII XXXVIII | 347S31 | X 6 CrNiNb 18 10 | X 6 CrNiNb 18-11 | 08KH18N12B |

| 347 H | SUS F 347H | X 8 CrNiNb 1811 | X 7 CrNiNb 18-11 | |||||||

| 904L | 1.4939 | Z 12 CNDV 12-02 | ||||||||

| X 20 CrNiSi 25 4 | 1.4821 | |||||||||

| UNS31803 | X²CrNiMoN²²V | 1.4462 | ||||||||

| UNS32760 | X 3 CrNiMoN 25 7 | 1.4501 | Z 3 CND 25-06Az | |||||||

| 403 | X 6 Cr 13 X 10 Cr 13 X 15 Cr 13 | 1.4000 1.4006 1.4024 | Z 12 C 13 | SUS 403 | X 12 Cr 13 | XXIII II | 403S17 | X 10 Cr 13 X 12 Cr 13 | X 6 Cr 13 | XII Rei XIII |

| 405 | X6CrAl13 | 1.4002 | Z 6 CA 13 | SUS 405 | X6CrAl13 | 405S17 | X6CrAl13 | X6CrAl13 | ||

| X 10 CrAl7 | 1.4713 | Z 8 CA 7 | X 10 CrAl7 | |||||||

| X 10 CrAl13 | 1.4724 | X 10 CrAl 12 | 10Kh13SYu | |||||||

| X 10 CrAl 18 | 1.4742 | X 10CrSiAl 18 | 15Kh18SYu | |||||||

| 409 | X 6 CrTi 12 | 1.4512 | Z 6 CT 12 | SUH 409 | X 6 CrTi 12 | 409S19 | X 5 CrTi 12 | |||

| X 2 CrTi 12 | ||||||||||

| 410 | X 6 Cr 13 X 10 Cr 13 X 15 Cr 13 | 1.4000 1.4006 1.4024 | Z 10 C 13 Z 12 C 13 | SUS 410 | X 12 Cr 13 | XXIII II | 410S21 | X 12 Cr 13 | X 12 Cr 13 | XII Rei XIII |

| 410 S | X 6 Cr 13 | 1.4000 | Z 6 C 13 | SUS 410S | X 6 Cr 13 | XXIII I | 403S17 | X 6 Cr 13 | 08Kh13 | |

| 414 |

Officina

Commodum qualitatis:

Qualitas productorum nostrorum ad lineam moderandam in sectoribus olei et gasi non solum per processum fabricationis moderatam sed etiam per probationem producti finiti confirmatur. Experimenta typica includunt:

1. Experimenta non destructiva

2. Experimenta hydrostatica

3. Moderationes superficiei ornatae

4. Mensurae accuratae dimensionalis

5. Experimenta flare et coniformia

6. Examinatio proprietatum mechanicarum et chemicarum

Applicatio tubi caillaris

1) Industria instrumentorum medicorum

2) moderatio temperaturae industrialis temperaturae ducta, sensoribus adhibitis tubis, thermometro tubulari

3) Tubus centralis industriae curae calamorum

4) antenna micro-tubularis, varia genera antennarum parvarum praecisionis chalybis inoxidabilis

5) Cum varietate capillaris electronici parvi diametri ex chalybe inoxidabili

6) Acus perforatoriae gemmarum

7) Horologia, imago

8) Tubus antennae autocineti, antennae vectes tubis utentes, tubus antennae

9) Instrumenta incisionis lasericae ad usum tuborum chalybis inoxidabilis

10) Instrumenta piscatoria, accessiones, Yugan cum possessione

11) Diaeta cum capillari chalybeo inoxidabili

12) omnes generis styli telephonorum mobilium stylus computatralis

13) Industria tuborum calefactoriorum, industria olei

14) Impressores, acus arcae silentis

15) Tubum chalybis inoxidabilis dupliciter fusum, in apparatu fenestrarum iuncto adhibitum, extrahe.

16) Varietas tuborum industrialium ex chalybe inoxidabili, diametro parvo praecisionis,

17) Dispensatio accurata cum acubus chalybis inoxidabilis

18) Microphonum, auricularia et microphonum ad usum tuborum chalybis inoxidabilis, et cetera.